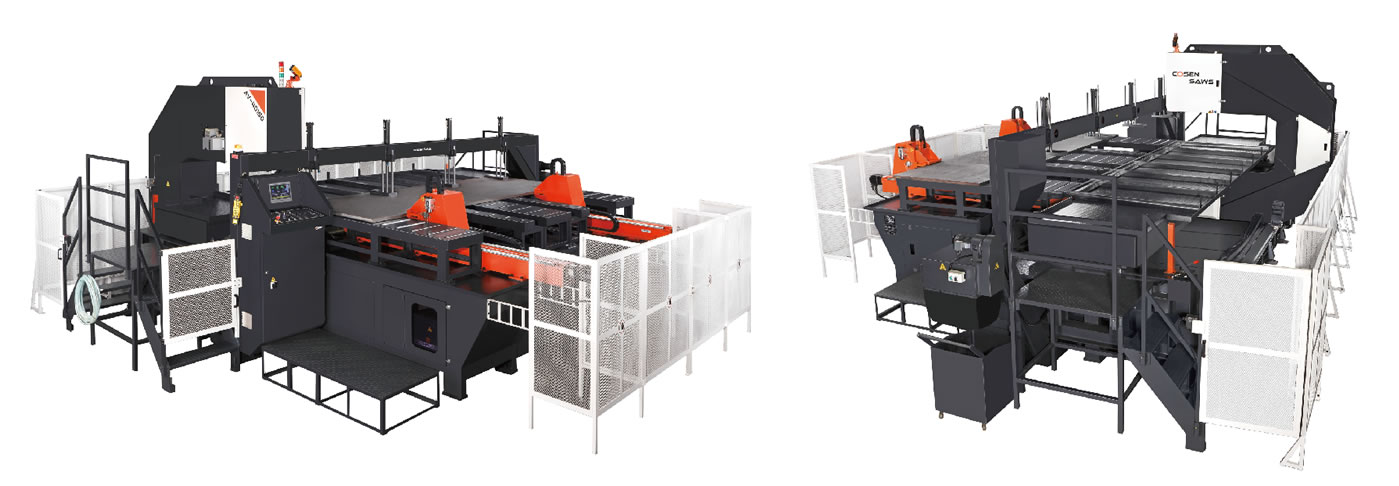

Cosen AV-40150 sawing machine

2 May 2024

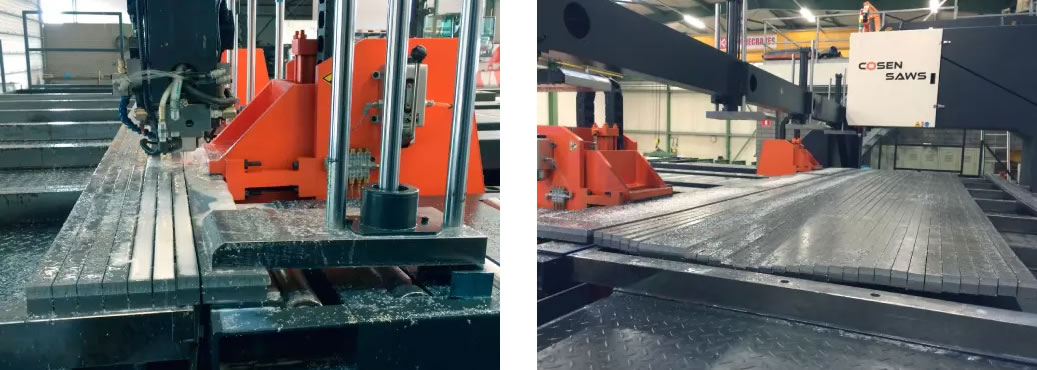

Some time ago the request was made for the supply of a fully automatic vertical band saw machine. The material to be sawn consists of large “Triplate” plates. This is explosion-welded sheet material with 3 layers consisting of steel, pure aluminum and corrosion-resistant aluminum. The plates with a size of approximately 4,000 x 2,000 mm must be sawn into strips of approximately 30 mm in a fully automatic manner. Preferably also unmanned after the material has been loaded with an automatic sheet feeder. In short, a challenge.

Ultimately, the customer ended up at Cosen. A large and specialized Taiwanese manufacturer of sawing machines represented by Electrotool BV. The machine was ultimately delivered by Van Dulst Techniek BV, a specialist in installing such production lines. It is a band saw machine with a movable saw head on 3 running wheels. The offset is no less than 1,500mm. The machine has a size of approximately 8 meters. x 6 m. and a height of 3.4 meters. and is equipped with two large movable clamps to pass the plate through. The machine has a weight of 24 tons. This concerns the Cosen AV-40150 vertical band saw machine. Although unique to the Netherlands, this is not very new so far. It is a sawing machine that is in principle available as standard from Cosen.

What is special about this vertical band saw machine

First of all, the fully automatic operation of the machine. The machine cuts the entire buffer of 1,500 mm after it has been loaded. The sawing machine is explained below for high-speed sawing with carbide band saw blades. With the Bahco TSX saw blades, cutting times are achieved that are at least one third of sawing times with conventional bi-metal saw blades. The sawing speed is approximately 170 m/min. at a feed rate of approx. 170 mm/min. The strips of exactly 3,850 mm are sawn in approximately 20 minutes. In addition, the service life of the saw blades is phenomenal. A service life of more than 1,200 meters becomes easy. clocked. This means at least 120 hours of net sawing time with one bandsaw blade in difficult-to-cut materials. This is all due to the enormous stability of the entire machine, but especially the saw head. The clamping with the special input clamps and the vertical clamping cylinders also ensures complete stability of the plate during the sawing process.

Cosen Predictive Computing system

In addition, the customer wanted to be informed if there was something wrong with the sawing machine. An important requirement for unmanned sawing. The sawing machine can then be checked to see why it is standing still. Preferably with a report of the fault. Cosen was also able to provide this with the new CPC unit. This is the new Cosen Predictive Computing system. This system even gives the customer the opportunity to detect the malfunction in advance, but more importantly to anticipate any upcoming malfunction. The saw blade is fully monitored, the status of the machine is specified, the efficiency of the sawing process is specified by means of various sensors placed in the machine and on crucial components. An estimate can therefore be made of what will happen when the machine is switched on at the end of the afternoon for a complete cycle. And this is precisely so important when unmanned sawing with such a sawing machine. All data is presented in a user-friendly manner and is stored in a database that records in the cloud.

Authorized employees can watch in real time how the sawing machine is running. This is simply done on your smartphone using an app. This can be downloaded from Cosen. Although this is already somewhat common on large CNC machines, Cosen is the first to introduce this app on band saw machines. Internet of Things, applied and fully focused on the sawing process. Machine utilization, production planning and maintenance can all be scheduled. This ensures great reliability of the production tool, in this case the sawing machine. This is the new production. Perhaps it is no coincidence that this technology comes from Taiwan, where the largest smartphone manufacturer in the world is located.

The customer has taken this last described option and is very pleased with it. The production is astonishing and exceeds all expectations. With this machine production can be increased without many worries. For more information about advanced sawing installations and Cosen sawing machines, please contact Electrotool.